What Is Centroid data? Centroid XY files are mainly used to place the surface mount parts on circuit boards. Centroid data is the machine file in ASCII text format called Component Placement, parts centroid, or pick & place file having component placement information. It can also be used in programming AOI machines to inspect circuit boards.

What Is Centroid Data?

Surface mount components are often placed on your PCBs using automated equipment. Our programmers use the Centroid file (an XY file, Insertion, Pick-and-place, or Pick-and-place file) to program these machines rapidly.

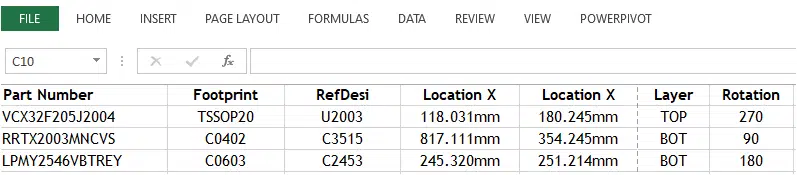

Centroid XY files contain the details of the position and rotation of each reference denominator that are supposed to be mounted on a printed circuit board. The format can vary, but in routine practice, centroid data find in the below order Part Number.

Most pick-and-place users will be familiar with the fact that, on most machines, you have the option to teach the board manually, which involves locating each device one by one with an overhead camera. However, that is extremely slow and impossible if the silkscreen is unclear if there is one.

How to Centroid Data from Gerber

The XY location of part placement can be in mil, an inch, or mm; it is calculated from the origin of the printed circuit board for the Centroid File. Here’s a breakdown of the Pick and place file formats that must contain the information below-

Reference Designator (RefDes)

The reference designator is known as a RefDes. The Bill of material and PCB markup are reflected in this figure. An unambiguous reference designator identifies an electrical schematic or printed circuit board. For Example, one or two letters followed by a number comprise the reference designator. C1002 and R13 are two reference designators,

Other than that, Designation Letters for electrical and electronic assemblies like resistors are referred to by the letter R, capacitors by the letter C, and relays by the letter K.

Location

The X/Y coordinate of the component from the printed circuit Board Origin. “LocationX” and “LocationY” describe the distance between the part and the board origin. It is important to have the part origin centered when using location values. Origin 0,0 of the board can be found in the lower-left corner. From the top of the board, looking down, the origin of the bottom of the board is in the lower-left corner. (0.0000″) is the preferred unit.

Rotation

On the top, the rotation goes counterclockwise, and on the bottom, it goes clockwise. Both perspectives are from the point of view of the top of the board. From the standpoint of looking at the top of the board, the bottom side parts are seen through the board. The rotation is in degrees and can be measured like 0,45,90..as given in CAD File during PCB design.

Layer

CAD layer designators do not necessarily refer to the top or bottom of the layer. The part can be at either the top or bottom of the board. Assemblers and PCB fabrication firms often refer to the top as the component side and the bottom as the solder side.

Pick and place file-formats Example.

Recommended File Format: .csv, .xls, and .xlsx.

Inputs to Generate X-Y Centroid data

In Surface Mount technology, generating and extracting Component placement files required Gerber data and Bill of Materials. After that, it was developed through the latest software. CAD software packages can generate Centroid files, but others are not available. So many manufacturers reverse engineer these manufacturing files to get Centroid files for machine programming. It usually takes hours and wastage of time and production.

We can use a circuit board reverse engineering process to generate the data. A circuit board reverses engineering (PCB RE, sometimes called “cloning”) is the process of developing fabrication and design data from a physical board that is identical or closely matched to that board. But this data is not necessarily malicious or aimed at intellectual property theft.

Best Gerber editor Software

Several tools let you perform the same task and rely on pattern matching. Following is a description of how to create a Centroid file using different programs.

GC-Prevue – The trial version of this software was hard to use, perhaps because I don’t do CAD work in my day-to-day job. Electronic manufacturing data can be viewed and printed using GC-Prevue, the industry-standard software. GC-Prevue reads all electronic manufacturing outputs that CAD typically produces.

FAB3000 – My current favorite not only doesn’t parse text, but it gives references to each component based on your imported component list, and no attempt is made to recognize the text. While GC is not as concise as other programs, the interface looks decent, and the software has several options you may find helpful if working in different formats.

GerberGrab – Apparently, it was once a commercial effort but is now free, and it works somewhat. It is possible to prepare and verify PCB data with GerberGrab for PCs using the numerous tools available in the software. It does read the silkscreen to generate a BOM that can then be matched with one imported by Versatronics GCPrevue (some versions).

Unisoft ProntoPLACE – Although it is very similar to Fab3000, you will notice loading it To program assembly machines, automatically generates part centroid rotation from Gerber data. Unisoft has provided shop floor automation software solutions to New Product Development for over three decades.

Conclusion – Wrapping it up

So, you understand that To program their pick-and-place machines and What Is Centroid data, PC board assembly houses require a centroid file (or x-y file). It doesn’t matter what you call it, but surface mount assembly robots need a magic file to determine where the components should be placed and how they should be positioned. The centroid is referred to as such. To set up a PCB, you need a centroid file. What is it, and what is its importance?

The manual teaching and entry method was used early but was slow and challenging; there is a method buy advanced interweaves to achieve the same goal. I looked for alternative tools used widely.