If you are involved in electronics manufacturing or prototyping, a benchtop reflow oven is crucial to ensure proper soldering. A right reflow oven is not only easy to install but also affordable in pricing.

As a Soldering Expert, I have worked on a lot of projects.

I have hands-on experience with 13-zone reflow ovens and mini desktop reflow ovens. We are here to make the final selection for purchasing the Best Low-cost reflow oven with the best features.

I’ve researched and tested hundreds of small reflow ovens for soldering options over the year to save you time and resources. I found that It is a smart investment to achieve precise and reliable soldering results at a very low cost.

In this post, we’ll explain key considerations while choosing the cheap reflow oven for reflow soldering in your budget. Further, we’ll also share the pros and cons of each product so that you can make more informed purchasing decisions for your needs.

Quick Product Comparison Table

Table of Contents

How We Test

Choosing the best benchtop reflow oven is a challenging task, especially when you are a beginner. To help you, I have carefully researched and tested the top options based on build quality, size, price, heating technologies, and customer support. My honest and unbiased reviews will help you to make an informed buying decision.

Due to that, I have several excellent recommendations that you can buy. I have listed the top 5 Best destop Reflow Oven shortlisted product research, analysis, and individual testing hours. Below are the three key factors. Based on that, you can select the best option.

- Pricing: In this segment, people are searching for the table top belt soldering oven. Because it requires small-batch products, pricing is also a critical deciding factor. Due to that, I tried to investigate high-performance desktop reflow ovens on a low budget.

- Hands-on testing: As an expert, I mounted the component on solder-paste printed circuit boards to test the performance of the Best Low-cost reflow oven. I set the profile according to the board and solder paste manufacturer guidelines.

- Research and Analysis: To determine the best DIY solder reflow oven, I picked the products that are easily accessible in the marketplace and analyzed the user’s ratings and feedback on the internet.

Mini reflow ovens are widely used in low-volume production, training applications, and reaping projects. The traditional hand-soldering methods meet quality and production volume demands. These cheap reflow ovens are ideal for low-volume and limited space areas.

SMD reflow profiles are explicitly designed for SMD (Surface Mount Device) components. These profiles allow the component to be placed on the board and heated to its melting point. Once it has melted, the solder will flow into all available spaces between the component leads and pads.

What is the Best Benchtop Reflow Oven?

As an expert in the field, I recommend the T962 table top reflow oven due to its great heating technology and excellent build quality in this price range. After considering your specific needs and budget, make a more informed purchasing decision.

If you’ve never used a soldering machine before, See our article on How to Solder Electronics Components. If you can, practice circuit boards. Remember, precise temperature control is crucial for achieving reliable solder joints. For that, ensure that you have set specific temperature profiles for optimal results.

After using and testing a ton of different mini reflow ovens from various manufacturers, here are my top picks for the best benchtop reflow soldering this year.

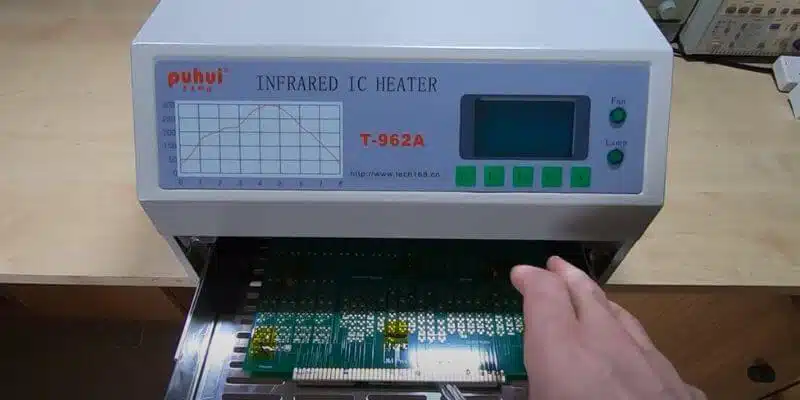

1. Happybuy Reflow Oven T962A

We’ve found that The T962 is a Low-cost reflow oven choice among hobbyists and small electronics manufacturers we tested. I love its userfriemdly interface that can handle PCBs up to 320mm x 360mm. If you prefer extra precise temperature control to avoid thermal stress on the components, it is a perfect choice.

We’ve tested over the years based on what’s available. We picked this reflow oven because It is a small engineering model prototype of electronics assembled at home.

The layout of the Happybuy Reflow Oven T962 is Ultimate. It is a microprocessor-controlled best DIY reflow oven, Arduino, for SMT and surface mount assemblies.

I appreciate how this best surface mount reflow oven works automatically by micro-computer control. I also Like this pro. The best cheap reflow oven has an ergonomic design with an Infrared reflow oven model, which is best suited for large welding areas for high efficiency.

The temperature is a valid reason for adopting fast infrared radiation and circulation of the wind for excellent performance. The equipment features input keys and an LCD for user interference and inputs. Other than that, the LCD Display design is decent for this best surface-mount reflow oven. It’s not just about size; it’s about efficiency, too!

Overall, the T-962A+ is a decent benchtop reflow oven for hobbyists and small businesses on a budget. I recommend it The T-962A+ because it is relatively affordable compared to other reflow ovens on the market.

Pros:

- Best Low cost reflow oven for accuracy,

- It can accommodate PCBs of up to 300 x 320 mm.

- It can be programmed to follow a specific temperature profile.

- Featured with a small footprint and Durable construction.

Cons:

- Upon completion of the batch, the beeping will begin. It could be more pleasant to hear.

- The oven does not have an automatic cool-down feature.

2. Happybuy Reflow Oven T962A

Compared with cheaper options, the Happybuy t962 reflow oven comes up with many advanced features. We’ve tested it for its high-end performance and seamless operations,

we’ve found that it features 1500W heaters If you prefer an extra accurate and stable temperature. I find It is a simple mini reflow oven that allows working in a larger soldering area. The size of the working zone is 300 x 320 mm. That is quite impressive.

I’ve personally used this low-cost reflow oven and find it is perfect for prototyping and small-scale assembly jobs. In real-world terms, the product comes up with a temperature range from 100℃ to 350 ℃, and the cycle time is 1~8 min.

We’ve found that the reflow oven featured an equipped exhaust fan to meet high-performance soldering requirements. We’ve tested its exceptional performance with advanced quality In real-world terms.

I also set up and tested the old models. Happybuy t962 is a beautiful Benchtop Reflow Oven that helps improve your soldering capabilities cost-efficiently. Based on what’s available, We’ve found It is compatible with solder double sideboard assembly.

Pros:

- Maximum power capacity of 1500 watts.

- Soldering machine with infrared heater.

- High-quality Best desktop Reflow Oven.

- Intelligent system for testing and controlling

Cons:

- Upon completion of the batch, the beeping will begin. It could be more pleasant to hear.

- The oven does not have an automatic cool-down feature.

3. AE-5010 Precision Mini Reflow Oven

If you are searching for a perfect prototype reflow oven that can ensure ideal temperature distribution, the AE-5010 Precision Lead-Free Mini Reflow Oven is the best option. AE-5010 is an attractive option you can trust to ensure perfect quality.

It’s nice to see how well the heat distribution works and how it has been designed so that the system automatically adjusts itself according to the needs of each room.

You can also see the current real-time temperature display on the LCD screen. The mini reflow oven is a lightweight stand-alone that makes it easier to access. Bodybuilding involves using heavy materials for its construction. The quality of this best reflow oven is reasonably ensured here.

I Like the features of efficient far-infrared heating elements for effective soldering. It is equipped with a DB9 Connector for connecting to a PC that works great. One can now efficiently operate the reflow oven software without making much effort.

Moreover, I’d like to confirm that the built-in internal microprocessor controls the temperature perfectly at precisely set temperatures. I appreciate this mini reflow oven from SMT Electronics because you can solder two-sided PCBAs simultaneously with excellent soldering quality. A lead-free desktop reflow oven is excellent for smaller-scale prototypes and production units.

Pros:

- Maximum power capacity of 1600 watts.

- Uniform heat distribution for best results.

- Featured with High-quality infrared heating.

- Wide Soldering area perfect for medium and large projects

Cons:

- It is a pricy small reflow oven.

4. Mophorn Best Desktop Reflow Oven

Mophorn Reflow Oven is a professional oven designed for reflow soldering. The Mophorn Reflow oven is a high-performance reflow oven designed for PCB assembly.

We’ve seen the Mophorn benchtop reflow oven has two heating zones. One zone is for preheating, and the other is for actual Soldering. It allows you to solder at higher temperatures without damaging the components.

We’ve been testing this reflow soldering machine for PCB manufacturing over the past nine years. We’ve found that it uses infrared heating technology to melt the solder on the surface of the circuit board.

We’ve tested the Mophorn Reflow T962A over the years, and In real-world terms, it is probably the most useful reflow soldering machine designed for electronics hobbyists and professionals. We’ve found that Its compact size and easy operation are perfect for home use.

I also set up and tested the old one but found it less efficient than this latest model. The only problem we’ve encountered with our model is their higher price as compared to other available options. Otherwise, it is the best desktop reflow oven option with this we’ve tested so far.

Pros:

- Compact size and easy to use

- A great option for beginners

- Precise Temperature Control

- Automatic Cooling System

Cons:

- It is a pricy small reflow oven.

5. X-Tronic’s Hot Air Rework

We’ve found that X-Tronic’s all-in-one hot air rework soldering iron station with a Preheater. I’ve personally been using it over the past two years; It is one of my favourite reworking equipment compared with cheaper options. I like it because it is a complete multipurpose tool for surface mounting, SMD, DIY, and Arduino assembly.

This small reflow ovens for soldering features Samsung Microcontroller PID technology, giving the user a complete digital experience. One Soldering is equipped with a 70W Soldering Iron, 500W Hot Air Gun, and 700W Preheating Station.

The 5040-XR2 is simply a hot air rework station designed for use in conjunction with a soldering iron. We’ve found this combination allows you to set components onto PCBs,

We’ve seen the 5040-Xr3 is a hot air reworking station explicitly designed for use with the 5040-Xr4 soldering iron. This station provides a high-temperature environment for soldering and reworking components.

We also looked at the 5040-XR2, which has been designed to provide maximum versatility in the field. It can be used as a benchtop unit or mounted on a wall. You can buy this device loaded with accessories like a fan, heater, thermostat, and timer.

Pros:

- In-One Hot Air Rework & Soldering Iron Station.

- Advanced Cutting Edge in Technology.

- 1270W Total Power Consumption.

- Intelligent system for testing and controlling

Cons:

- It is not a complete reflow oven.

How to Choose the Best Low cost reflow oven

Reflow ovens manufacture electronic components, such as printed circuit boards. They are so used for Soldering and other processes that require high temperatures. The reflow oven is where heat is applied to an object placed inside. The object is heated until it reaches its melting point. Once melted, the object solidifies again. This process is repeated several times to ensure all parts of the component are correctly soldered.

There are two types of reflow ovens: Convection ovens and Infrared ovens. Both types have their advantages and disadvantages. In this article, we will discuss what makes one better than another. We will also compare different models available in the market today.

The best benchtop ovens offer the highest quality features at the lowest price. To choose the right one for you, consider these factors:

Size:

Smaller models tend to be less expensive but may not hold up well against larger ones.

Price:

You can get good deals on used ovens, especially from stores that sell appliances. But don’t buy an older model unless you’re sure it works properly.

Energy efficiency:

Choose an energy-efficient mini reflow soldering machine if possible. They use less electricity than standard models.

Warranty:

The warranty will cover repairs and replacements if something goes wrong.

Durability:

Ovens are made of different materials, including stainless steel, glass, ceramic, cast iron, and enameled steel. Stainless steel and glass are the most durable but cost more. Cast iron and enameled steel are cheaper options.

types of reflow ovens

There are two types of reflow ovens convection ovens and Infrared ovens. Both types have their advantages and disadvantages. In this article, we will discuss what makes one better than another. We will also compare different models available in the market today.

Convection Reflow Ovens

Convection reflow ovens are the most popular type of reflow ovens. They consist of a chamber with heating elements—hot air and heat for the objects placed inside. The advantage of a convection reflow oven is that it provides fast heating and cooling rates. It can be used for both large and small volumes of products.

The disadvantage of convection reflow is that it requires constant monitoring and adjusting of temperature. The solder joints will not melt entirely if the temperature is too low. On the other hand, some components might burn if the temperature is too high.

Infrared Reflow Ovens

The second type of reflow oven is an infrared reflow oven. Unlike a convection reflow oven, which uses hot air to heat the object, an infrared reflow oven uses radiant heat. Radiant heat is emitted from a source and travels straight toward the object. The advantage of an infrared reflow oven is that there is no need to monitor or adjust the temperature. Also, it has less maintenance cost than the convection reflow oven.

However, the infrared reflow oven takes longer to heat up than the convection reflow oven. Therefore, it is best suited for smaller volumes of products.

The Reflow Soldering Process

Most soldiers were applied manually with a brush or stencil in the past. Today’s automated systems apply solder paste directly onto the component leads. A reflow oven heats the leaded part until all the solder melts. Once the

s is used, join two or more metal parts together. The name o process involves heating a solder paste on one surface and then pressing it down on the other surface, which causes the solder to flow into the joint between the two surfaces.

The first step in the reflow soldering process requires preheating the component leads so that the solder paste will melt when pressed onto it. Once the lead tips have melted, the solder paste can be applied. After applying the solder paste, the component must be placed on a flat surface with its leads facing upward.

A heated tool called a reflow iron is then used to apply pressure to the component. The solder paste melts and flows around the component as the pressure is applied, forming a solid connection between the component and the substrate.

The most common reflow soldering machine is an automatic reflow soldering machine. Automatic reflow machines have three main components: a conveyor system, a heater, and a control unit. The conveyor system moves the components past the heater, where the solder paste is. The control unit controls the temperature of the heater and the heat application duration.

Reflow soldering equipment can also be manually operated. In manual operation, the operator places the component on a fixture and presses a button to initiate the heating cycle. Manual ref ow soldering equipment consists of a single heater and a timer.

What is the SMD reflow profile? How do I set the reflow profile?

The SMD reflow profile has become the standard for high-speed soldering applications. It provides a consistent temperature profile across the entire board area. That allows for faster and more reliable soldering operations. This profile provides a constant temperature throughout the entire board area. It is ideal for high-speed solderings, such as wave soldering or hot air solder leveling (HASL).

To change the reflow profile settings, select the desired profile from the menu at the bottom of the screen. You may also press the Menu button to access these options. The SMD re low profiles is recommended when performing high-speed soldering operations, such as through wave or HASL.

After setting up your profile, you will see a Save icon next to each profile name. Clicking on this icon will allow you to save your profile. You may later load this saved profile by clicking on the Load Icon.

For example, if you are soldering multiple boards simultaneously, using the general reflow profile could cause overheating. There is no need to adjust the heat output when using the SMD reflow.

How Does a Benchtop Reflow Oven Work?

The reflow oven is the most versatile and commonly used oven for Soldering. The term “reflow” refers to a process where solder is applied to an electronic component, heated to melt, then cooled so that it solidifies into place. A reflow oven is used to perform all types of reflows, including wave, HASL, and solder paste reflows.

The reflow oven consists of two main parts; the heating chamber and the cooling chamber. The heating chamber houses the heating element, which heats the air inside the chamber. The air is blown out of the heating chamber via the exhaust port near the oven’s back. The exhaust port is connected to the cooling chamber.

The cooling chamber contains a fan that pulls cool air outside the oven and blows it over the heating elements. This cooling helps keep the heating elements warm and thus maintains their optimal operating temperatures. The exhaust port is also connected to the cooling chamber to pull the air out of both chambers.

The heating chamber is usually aluminum, while the cooling chamber is typically stainless steel. Both chambers have holes in them to allow the air to flow freely. The heating element is placed inside the heating chamber, and the fan is mounted on top of the cooling chamber. The fan draws air through the heating element and pushes it out of the heating chamber through the exhaust port.

Types of cheap reflow oven

There are three basic types of reflow ovens:

- Convection Reflow Oven – The convection reflow oven uses hot air to heat components. It has one heating chamber with a single heating element. The conventional reflow is ideal for small-volume production because it allows fast heating and precise temperature control.

- Forced Air Reflow Oven – This reflow oven uses forced air to heat components. The forced air reflow oven has two separate heating chambers. One chamber houses the heating element, and the other holds the components being soldered.

- Each chamber has its own heating element and fan. The fans pass air through the heating chambers and expel it through the exhaust ports. These ovens provide excellent uniformity and repeatability. They are best suited for high-volume production.

- Infrared Reflow Oven – An infrared reflow oven uses infrared radiation instead of heat to heat components. Infrared reflow ovens are very similar to convection reflow ovens, except they use infrared energy rather than hot air.

Like convection reflow ovens, infrared reflow ovens are great for small-volume production. However, t ey requires more time to heat components than convection reflow.

FAQ

Q. Can you reflow the solder in the oven?

A. You can reflow solder in the oven. Still, it will not give the recommended quality of a product because reflow ovens are precisely temperature-controlled and work on some dedicated settings. One more thing, the reflow oven contains the cooling zone as well.

Q. What are reflow ovens used for?

A. The reflow ovens are used for soldering printed circuit boards in mass production. The output of the reflow oven depends on the selected types. It can generally take solder thousands of printed circuits in an hour.

Q. How do I choose a reflow oven?

A. A reflow oven is a device soldering electronic components such as resistors, capacitors, transistors, etc. The reflow process creates a permanent bond between the component and the circuit board. It is done by heating the solder to a temperature above the melting point of the solder. Once the solder has melted, the board is placed into the oven, remaining until cooled.

Q. How do you reflow solder at home?

A. Reflowing solder is easy. You need a soldering iron, flux, solder, and clean hands. First, heat your soldering iron until it gets red hot. Then, apply a small amount of flux to the iron’s tip. Next, place the solder onto the iron tip and then touch the solder to the joint. Finally, you e your fingers to remove excess solder from the joint.

Q. What is the difference between reflow soldering and wave soldering?

A. Reflow soldering is when you use solder paste to connect components on the board. Wave soldering is when you put solder directly onto the pads on the board. The advantage of using solder paste is that you don’t need to worry about getting the solder into the right place. However, If you want to do some fine-tuning, you should use wave soldering.

Q. What is an SMD reflow oven?

A. The SMD reflow oven is soldering components onto printed circuit boards. This process is called surface mount technology, or SMT. SMD reflow ovens are used in manufacturing electronic devices such as computers, cell phones, and other consumer electronics.

Conclusion

We’ve tried other desktop SMT reflow ovens before, but they don’t do what you need them to do. They take to heat up, and they never seem to reach the right temperature. The Best B benchtop Reflow Oven is the only oven you’ll ever need. It’s designed to bake evenly and rapidly and includes a digital timer and temperature controls.

The Best Benchtop Reflow oven heats up quickly and reaches the perfect temperature in less than 10 minutes. I hope you have selected your winning product. Further to any issues, you can check the buying Guide or comment on your query below.

Expert Tips and Sources

- Reflow Ovens Selection Guide: Types, Features, Applications

- The Reflow Soldering Process – PCB Assembly – Eurocircuits

- What Is Reflow Soldering? | Soldering

- How to do SMD Reflow Soldering properly! || Hot Air VS Sand VS Reflow Oven

How to do SMD Reflow Soldering properly

This video shows you how to install a new oven and Reflow Soldering correctly.

Related Posts