The solder post machine is a ubiquitous and widely used tool for electronic circuit boards and the tinning of wires. The main disadvantage of soldering pot station use is that it requires a lot of investment. So needed, a large production volume is to compensate for the equipment cost.

Welding and Soldering Baths are small, temperature-controlled pots that are handy in electronic soldering. A slight dip soldering machine is ideal for tinning the ends of stranded wire leads. Nothing can beat a solder pot. It is an excellent tool. The Lead-Free Soldering Pot is for dip soldering of small circuit boards for small commercial locations and electronic shops.

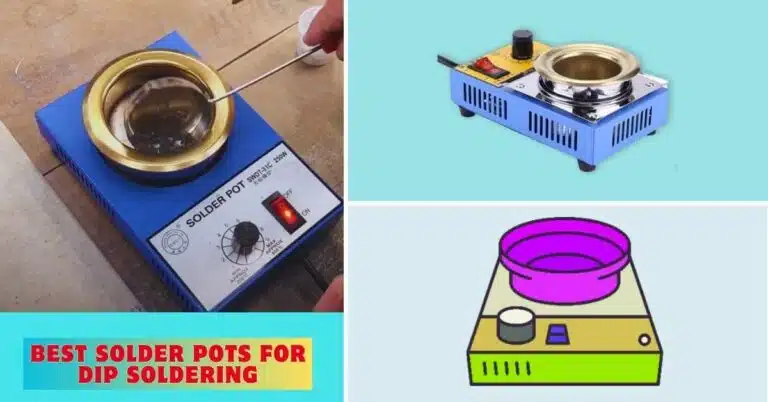

As beginners, it is tough to choose the best Lead-Free Solder Pot, especially when you are not aware of all the features and layouts of the equipment. That’s why we decided to review the 5 best solder pots available on the market so that you can find the most suitable options for your needs.

How we picked and Tested

Safety Features

Safety is of the utmost importance when handling higher-temperature molten solder. You see, Dip Soldering Pot for Households is inherently dangerous. It is essential to buy a Best Dip Soldering Pot for Industrial and home Uses with internal fortifications that prevent overheating, fires, and explosions.

Cleaning

You’d be wise to spend your money on a durable Lead-Free Solder Pot. While selecting a solder pot, you must consider that the pot must be adequately cleaned before starting the work. It is a widespread activity, so one must focus more on it.

Temperature

The temperature is one of the most important factors when choosing the Best Solder Pots. Whenever you buy a Best Dip Soldering Pot for Households, you can always look for something extra. A silver pot is a small pot that is well-controlled in temperature. This factor is crucial when selecting Best Solder Pots since melt materials can be pretty high.

Size

There are many different sizes of Best Solder Pot. Despite being extremely portable, they can take a while to melt the Soldier and require a higher temperature. It will take half your repair station if you decide to keep it in your soldering job. Others are compelling and include solder pots but are equally heavy beasts that are a hassle to maneuver any distance.

Comparison of our top 7 Best Solder Pots?

The Best Solder Pot that I and field professionals recommend is the Hakko FX300-03 Lead-Free Soldering Pot. Hakko FX300 is the best option because of its high quality, ease of use, and featured with an affordable price tag. I checked on the internet and found that thousands of people have tried them, and they are really happy with the results.

Here are some of the best solder bath machines.

1. Hakko FX300-03 Lead-Free Soldering Pot

Coming up with beautiful features like fast heating, Compatibility with Lead-Free solders, and a Low-cost system, It is one of the Best Solder Pot on the list that will always provide you with the best performance. This slight dip soldering machine provides regular operation at an excellent performance level.

This Best Solder Pot station provided a top performance on a daily basis jobs. It is designed so that it offers a low-cost system with optimum efficiency. It is a beautiful manual dip soldering machine for improving the soldering quality.

The solder bath machine price is high, but it provides value for money. This Lead-Free Soldering Pot is uniquely designed to offer extraordinary customer satisfaction.

Pros:

- Ensures long-lasting results.

- Easy to maintain options.

- Compatible with Lead-Free solder.

- For optimum performance, the boiler is made of titanium alloy.

Cons:

- A little bit pricy compared with others.

2. CM161 Soldering Pot Station

Coming up with a wide range of advanced features such as an influential power heater, 1000W power, and titanium alloy-made boiler CM161 Lead-Free Soldering Pot is an attractive option. It is a dedicated small dip soldering machine for high-end operations.

This product has many features like 5.7kg, Pot size, Huge Range: 200℃,~500℃, and temperature setting and locking function. It added more to it, featuring a power heater reaching 842℉ temperature within 30 minutes. That is amazing for seamless operations.

If you are looking forward to a reliable Best Solder Pot station with multiple features, the CM161 Lead-Free Soldering Pot is a perfect selection.

Pros:

- Ensures quick heating with a big power heater.

- Easy to maintain options.

- Compatible with Lead-Free solder.

- Enhance the engine power efficiency.

- Fast heating with an accurate onset temperature

Cons:

- Equipped 230V, 50Hz with Japanese plug.

3. Aven 17100 PCB dip Soldering Machine

The model we are looking at in the Best Solder Pot list is Aven 17100-150 Lead-Free Solder Pot. The Best Solder Bath Machine is also equipped with excellent thermal stability. That quickly liquefies Solder with a pot capacity of 500g.

The Crucible is made from stainless steel with a uniform coating of titanium plating. It’s advantageous as it increases the overall lifespan of the Lead-Free Solder Pot.

Why Did We Like It?

The Solder Pot is also equipped with a Heating element of 150W, ensuring a proper melting of Solder, plastic, resin, and more. Much like the Best Solder Bath Machines out on the market, it is best suitable for tinning the ends of stranded wire leads and dip soldering the printed circuit board assembly.

Another great thing about this best Lead-Free Solder Pot is that the Solder pot size of the device is 50mm (1.96in) in diameter. It is sufficient for small commercial use and other home workshop applications. It features a corrosion-resistant coating of the stainless steel wall for a long life span.

It is very compact and lightweight. The total weight of this Item is only 1.3 pounds. That is an essay to carry from one place to another. The overall design is simple and easy to use. It is highly recommended for small electrical parts and dip-soldering small circuit boards.

Pros:

- Lead-Free Solder Pot – 150W.

- Suitable for melting Solder, plastic, resin, and more.

- Using this device, materials can be kept at the desired temperature for an extended period.

Cons:

- Temperature cannot be known accurately due to the absence of an inbuilt thermostat.

4. KLT-360 Best Soldering Pot

The next best Lead-Free Solder Pot we are looking at is from TOMALTIC Store, known as KLT-360 Solder Pot Titanium Alloy.

That is also a fantastic quality product with a solid stainless steel body. You need to know the solder pot metal that is very important for device life.

Why Did We Like It?

The KLT-360 Solder Pot aims to simplify everything by ensuring that the consumer doesn’t have any bad experiences. It is a reliable and affordable device with a lot of multiple features. That is the Best Dip Soldering Pot for Household and Industrial Uses.

Most people don’t realize the importance of the soldering pot until they lose the quality efficiency of production outputs. So selecting the right tool for the right project is crucial. That is why we have chosen a great product to meet your requirements.

Pros:

- Less Melting Time:3-8min.

- Max Temperature: 80°c.

- Made of Good quality stainless Steel Pot.

Pros:

- No such Specific.

5. Twinkle Bay Welding and Soldering Bath

The following Product in our Best Solder Pot is the Twinkle Bay Lead-Free Solder Pot. Twinkle Bay uses a high-quality Soldering Bath made of stainless steel board to manufacture this best Lead-Free Solder Pot.

Why Did We Like It?

These unique Lead-Free Solder Pots are ideal for tinning stranded wire leads’ ends. You can also use them for re-tinning soldering iron tips and dip soldering small circuit boards with perfect temperature accuracy.

In addition, Twinkle Bay Best Dip Soldering Pot for Households has a Pot solder capacity of 2300g / 81.1oz, which is enough for industrial usage.

Overall, Twinkle Bay is the Best Dip Soldering Pot for households and industries. Uses an impressive selection of multiple features. It is recommended to buy for hobbyists and homemakers with easy-to-use functions.

Pros:

- Excellent heating and provide excellent thermal stability

- Stepless adjustable temperature from 200°c to 480°c

- Compact size for easy storing.

Cons:

- For the pot to work, a large amount of Solder is required.

6. Aidetek CM161 – Best Solder Pots

Why Did We Like It?

The final product on our list is CM161 Best Solder Pots. It has a 1000W and 5.7kg capacity with a big power heater Best Dip Soldering Pot for Industrial Uses. It is an excellent device that reaches 842℉ within 30 minutes only.

The best part of this CM161Best Solder Pots is that it has a temperature setting and locking function that never allows being affected by faulty operation. Soldering irons can also be placed in CM161. You do not have to worry about damaging the working surface when putting it aside with a holder.

Pros:

- The boiler is made of titanium alloy

- With temperature setting and locking function

Cons:

- Recommended for big jobs.

7. Jameco Benchpro soldering pot station

I came across the Jameco Benchpro Solder Pot nearly a year ago. It holds up a Capacity of 1KG to 2.2lbs (1KG) of solder bar. This vast and perfect selection is for industrial as well as heavy-duty applications. In other words, we can say that it is the Best Dip Soldering Pot for Industrial Uses. It is the perfect choice for small as well as large projects.

Why Did We Like It?

Jameco Benchpro Solder Pot is a lead-free version Made from stainless steel. To increase the pot’s life, it is coated with titanium plating. That is also essential for safe work environments.

The Regulated Temperature range is 420-450 Celsius, enough for melting Solder in minutes. Thus it helps to save productive time by rapid solder melting. Jameco’s soldering bath is the Best Solder Bath Machine, symbolizing quality and durability. It is a perfect solution for Ideal for tinning stranded wire lead ends with accuracy and higher capacity.

Built with durable materials, the unit lasts for a very long time. Despite being full, the bottom of the pot provides good stability. Further, the pot is constructed from lead-free materials, meaning that users can melt materials that are not standard.

Pros:

- Made from stainless steel with titanium plating promoting.

- Perfect for projects from small to large.

Cons:

- An on/off switcher is not provided.

Best Solder Pots Buyer’s Guide

This buyer’s guide considers the crucial features for selecting each Best Solder Pot. Discuss these critical parameters in more detail to understand why they are essential and impact functioning.

When buying Best Solder Pot, you have two options, buying for large volume production requirements or a general-purpose use. You certainly can’t count the number and kinds of Solder Pot available. We had to undertake extensive research to find the Best Solder Pot to meet your project requirements.

To discuss the features of this product, it’s important to touch on how it’s used. Molten Solder can be incredibly dangerous and scary when done improperly. We do not want any injuries, even though this list maintains a minimum safety standard.

There are hundreds of options out there. So We have carefully listed the crucial factors you need to consider when buying Best Solder Pots. It will help you to meet project requirements.

Capacity

Ideally, it would be best to get Best Solder Pots to meet your project’s needs and requirements. It is a simple yet clever addition that you plan to work with with tiny SMD components, Smartphones, or other simple tasks. It is recommended to select the soldering pot with a lower capacity. That also helps to get good quality solder joints and also saves power.

Besides, larger projects ensure a smoother user experience and speed production, which may require different sizes of pots.

Warranty

Purchase of this kind can be expensive. You can buy solder pots on Amazon. If you purchase it as a backup in an emergency, you won’t need it immediately, and problems will not appear immediately, either. Therefore, you should inquire about warranty coverage. The standard warranty for most of these products is five years. They cover several hundred years in some cases.

Be sure to research the company as well as the warranty. When a company’s customer service is non-existent, it is pointless to offer a warranty. Furthermore, you will often be required to pay for shipping the faulty product back to the company for repair. Buying a new one will take much shorter and more expensive than redeeming warranties on these heavy items.

Top Rated Best Lead-Free Solder Pots for Dip Soldering

How to Solder PGA components and connectors follow by Solder Pot

Procedure

- The clean work area of any contamination, oxides, or residues. Attach the correct nozzle to the solder pot.

- Ensure that the soldering pot solder has the correct temperature.

- Heat the nozzle by flowing the Solder through it until a clear Solder flow is obtained.

- Set the timer for the amount of time the solder fountain runs.

- The area around the rework site may be masked with high-temperature-resistant tape or similar material to protect the adjacent area during rework.

- Preheat the board to the desired temperature, depending on the component restrictions and the board Tg material.

- Place the part in the correct position on the board.

- Flux the bottom side site where the component is together with the component pins. Place the board on the pallet over the nozzle.

- Adjust the distance between the board’s bottom side and the nozzle. The melted Soldier should be able to reach the bottom side of the board. Turn on the solder fountain and start the timer.

- As the Solder in the holes reflows, the component may be reoriented to drop into the holes.

- At the end of the timer cycle, wait for at least 5 s for the Soldier to solidify and remove the board.

- Clean as applicable and inspect to established quality requirements.

How to Repair and rework

General information about the PBA repair and rework process is given below. If a component is sensitive to rework, the component rework requirements overrule. The performing manufacturing site or service center is responsible for the repair’s quality according to the product’s production process specification According to IPC Standards.

- Attached materials – The materials and processes used for repair and rework must be selected such that their combination fulfills the requirements of the finished product.

- Flux residues – Excessive or dark flux residues shall be cleaned with isopropanol. Burnt flux can turn into conductive carbon compounds and shall permanently be removed.

- Baking of PBAs before reworking – Before hot air reflow, it is crucial to ensure that all components subjected to high temperatures that could cause damage should be evaluated for required bake-out of moisture. The times and temperatures for baking out of moisture for different components can be found in the latest revision of IPC/JEDEC J-STD-033. If this standard’s baking times and temperatures are followed, all (or nearly all) absorbed moisture will be baked out.

- Component handling – Moisture-sensitive components must be handled and stored according to IPC/JEDEC J-STD-033’s latest revision.

- Preheating – bottom heat – Requirement-specific methods require using a bottom heater during repair to preheat the board and level out the ΔT on the PBA. It will also minimize thermal stress. The general temperature on the PBA surface should not exceed 150°C (or according to the repair method on a specific package specified below) to minimize intermetallic growth and thermal stress on the PCB.

- Manual Soldering station – The soldering tip temperature shall be a minimum of 315°C and a maximum of 360°C for tin-lead soldering and between 360°C to 450°C for lead-free soldering. Do not use higher temperatures than necessary. Too high temperatures can cause damage and cracks due to thermal stress on sensitive components, e.g., ceramic components like capacitors.

- Manual hot-air – Secure that the component is to be repaired and the areas around this component are not overheated. If there is doubt that the maximum component or board temperature cannot be kept, a BGA repair machine or another repair process shall be considered to ensure high process control. Too high temperatures can cause damage and cracks due to thermal stress on sensitive components, e.g., ceramic components like capacitors.

Related Posts

1. Best Stained Glass Soldering Iron in 2022 (My Top Picks)

2. 7 Best Soldering Tip Cleaners in 2022 (Top 7 Reviewed)

3. How to Remove Solder from Circuit Board 2022 (Ultimate Guide)

4. Top 5 Best Solder Fume Extractors to Buy in 2022

5. How to Solder Without Soldering Iron (Step By Step Guide)